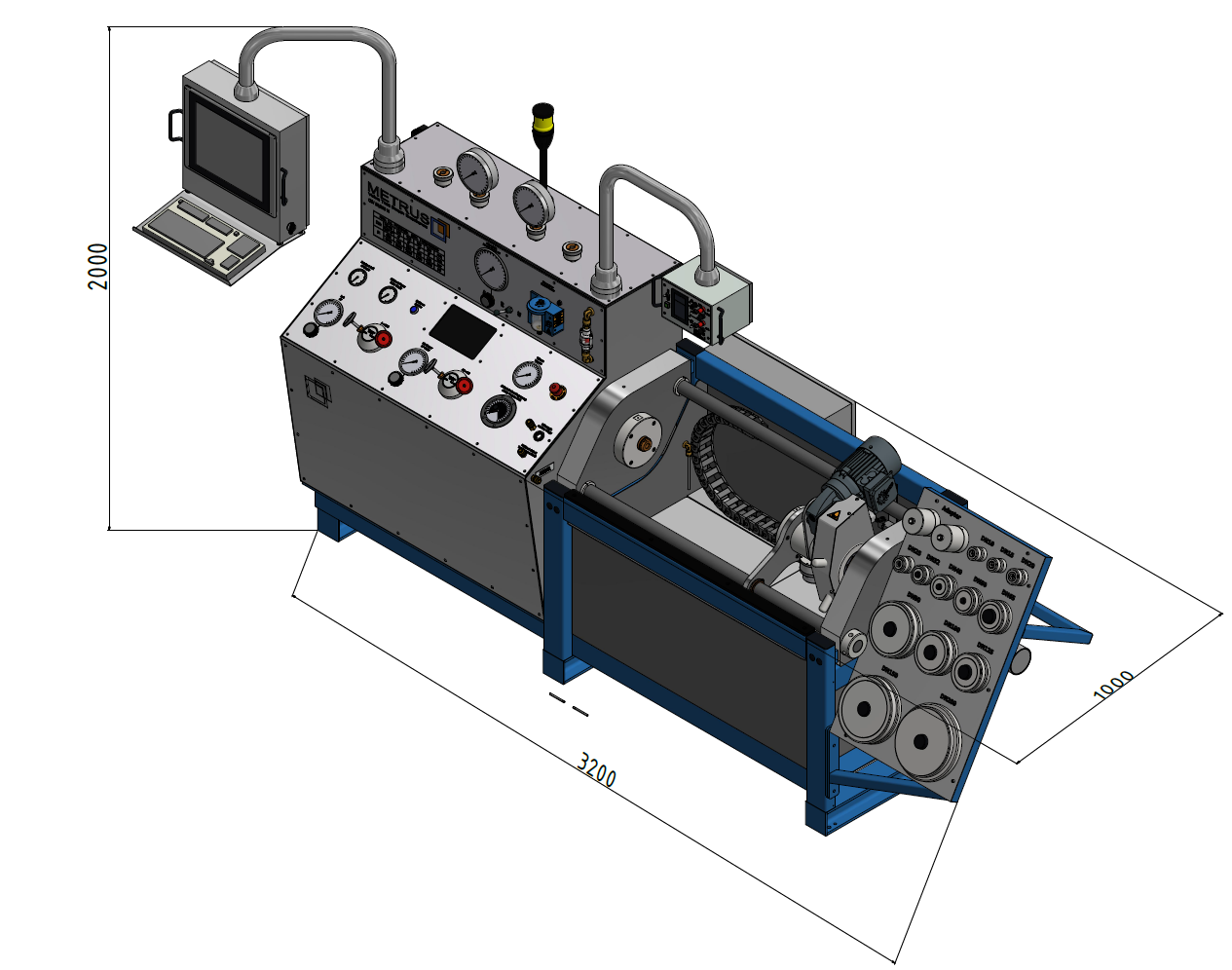

CSV 50/200

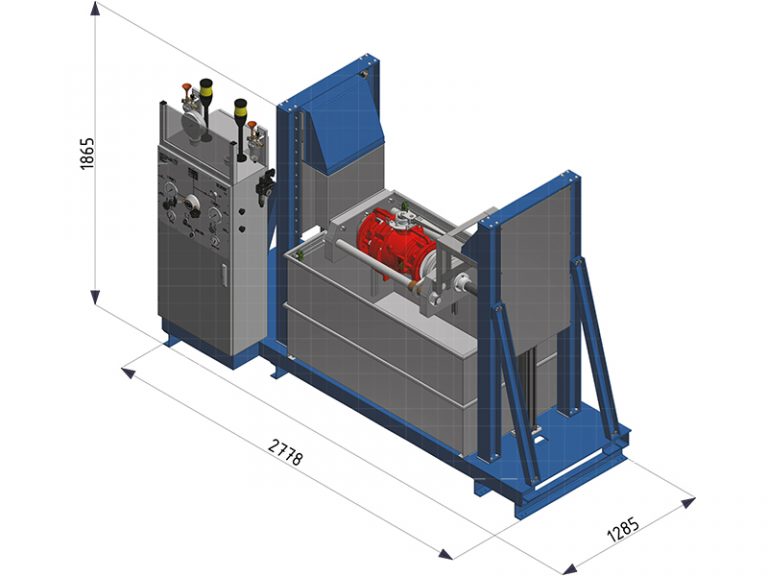

The METRUS test bench CSV 10/150 UW is designed for underwater testing (pressure and leak testing) of control and shut-off valves with straight passage and nominal sizes ranging from DN 15 (½") to DN 150 (6"). Tests for shell tightness and seat tightness can be conducted. The sealing of the valves under test is achieved using O-rings in the automatic sealing heads.

The control stand is mounted at a 90° angle to the immersion basin on a common base frame. Operation of all functions is carried out via the control stand, which is clearly labeled and positioned on the front panel. The clamping of the valve under test is motorized and performed in a column frame with an adjustable threaded spindle. The immersion of the clamping unit into the basin is controlled electrically via a two-hand operation for safety.

The required test pressure is available at the pressure inlet valve and can be read on the high-pressure (HP-air) or low-pressure (LP-air) gauges located on the front panel, or on the corresponding test gauge mounted on top of the control stand. The test gauges can be connected tool-free and without significant effort using METRUS quick-connect fittings.

The test bench is equipped with two bubble counters on the control panel for seat leakage testing, enabling precise observation during the testing process.

Figure may contain options.

Basic features

- Clamping range: DN15-DN150 ½''- 6''

- Clamping force: 10 tons

- Way of clamping: automatic sealing heads

- Stainless steel clamping table

- Safe 2 hand operation

- Shell test with air up to 40 bar / 580 PSI

- Seat leakage test with air up to 40 bar / 580 PSI

- Bidirectional seat leakage test

- Bubble counter on each side

- Stainless steel control panel

- Anodized, chemical resistant front panel

- Stainless steel water tank

- Integrated water tank lights

- Gauge quick connection for tool free change of gauges (2x)

- METRUS Precision valves

Options

- Gauge turret for 4+1 gauges

- Safety pressure limitation system

- CRS - Computer Registration System with panel PC

- Digital bubble counter

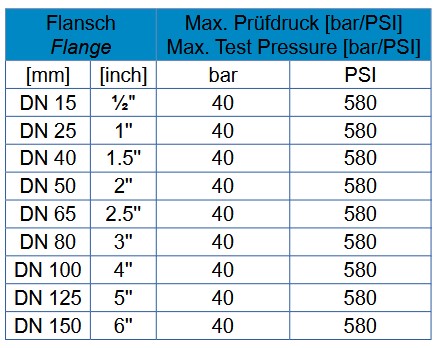

Max. Test Pressure

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

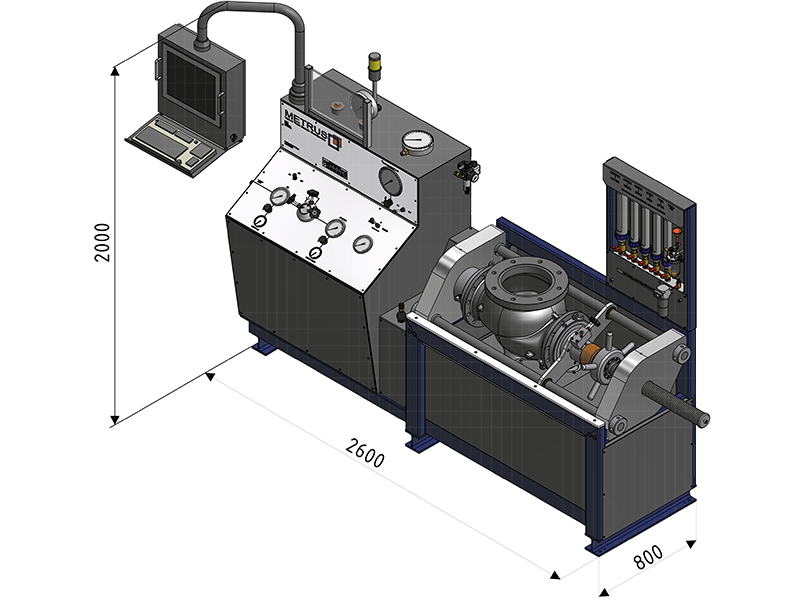

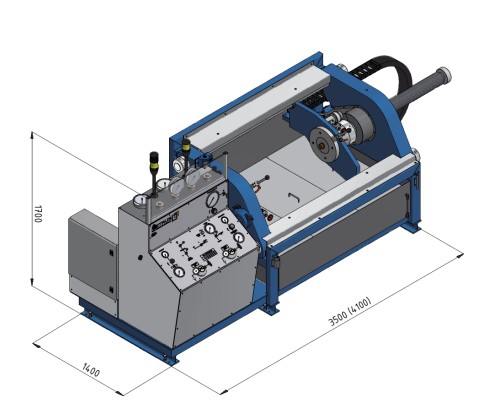

The test bench CSV 50/200 is designed for pressure and leak testing of shut-off and regulating valves with straight passage. The horizontal test axle is particularly suitable for testing regulating valves with mounted actuators.

The control stand is specifically designed for housing strength testing using high-pressure water (hp water) or low-pressure air (lp air) and for seat tightness testing. All devices are operated from the front side of the control stand, where all controls are clearly labeled for ease of use.

Figure may contain options.

Basic features

- Clamping range: DN10-DN200 ⅜"- 8"

- Clamping force: 50 tons

- Way of clamping: Automatic sealing heads

- Aux. pressure: Air up to 6 bar / 87 PSI

- Pressure piping: PN600 bar stainless steel

- Shell test with water up to 600 bar / 8700 PSI

- Seat leakage test with air up to 6 bar / 87 PSI

- Bubble counter

- Stainless steel control panel

- Anodized, chemical resistant front panel

- Stainless steel two chamber water tank

- Additional filling pump

- Maintenance free vacuum system

- Gauge quick connection for tool free change of gauges (2x)

- METRUS Precision valves

Options

- External testing adapter - for testing valves larger than DN200 / 8" beside the clamping unit

- Gauge turret for 4+1 gauges

- Set point adjuster 0-10V and 0-20mA for controlling actuators

- Safety pressure limitation system

- CRS - Computer Registration System with panel PC

- Protection doors

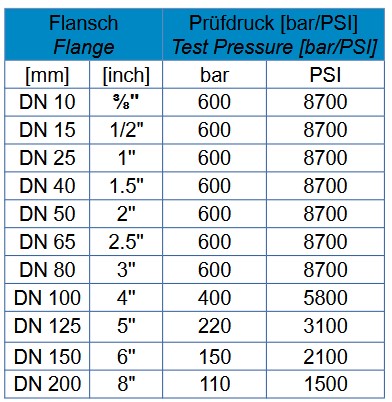

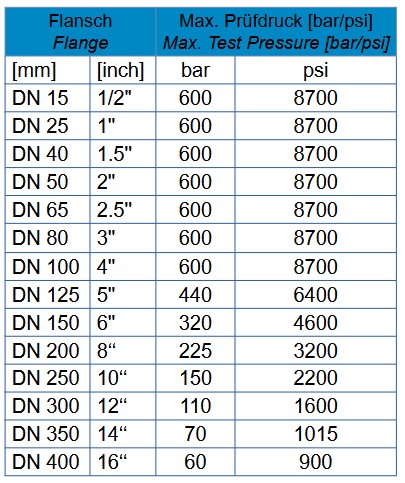

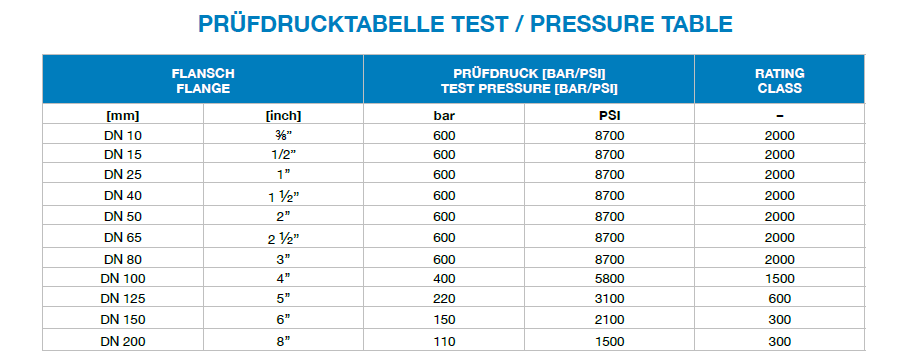

Max. Test Pressure

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

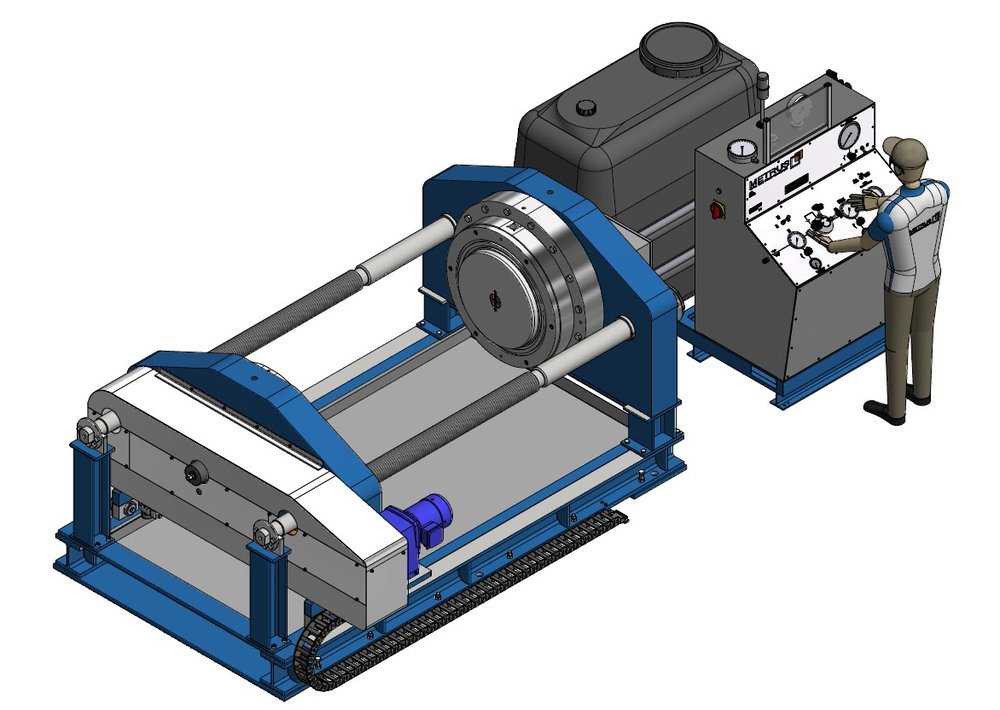

The METRUS CSV 100/400 Test Bench has been specifically designed for the testing of 2-way control valves with nominal widths ranging from DN 15 (1/2") to DN 400 (16"). Seat tests and casing tests can be performed using various test media.

The clamping unit of the CSV 100/400 can withstand loads of up to 1000 kN (≈ 100 t). The test pressure is set using the specially developed METRUS Precision Needle Valve V30.2 on the corresponding 2-way valve head.

All functions are controlled from the central console. The required test pressure is applied to the pressure inlet valves and can be read either from the test gauges on the control stand or directly on the PC via sensors.

Figure may contain options.

Basic features

- Clamping range: DN15-DN400 1/2“-16“

- Clamping force: 100 to

- Way of clamping: automatic sealing head

- Aux. pressure: air up to 6 bar

- Pressure piping: PN600 bar stainless steel

- Shell test with water up to 600 bar

- Seat leakage test with air up to 6 bar

- Electric driven clamping spindle

- Stainless steel control panel

- Anodized, aluminium front panel

- Stainless steel two chamber water tank

- Separated filling pump

- Maintenance free vacuum system

- Gauge quick connection for tool free change of gauges (2x)

- METRUS Precision valves

Options

- External testing adapter - for testing valves larger than DN400 / 16’’ beside the calmping unit

- Gauge turret for 4+1 gauges

- Set point adjuster 0-10V and 0-20mA for controlling actuators

- Safety pressure limitation system

- CRS - Computer Registration System with panel PC

Max. Test Pressure

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

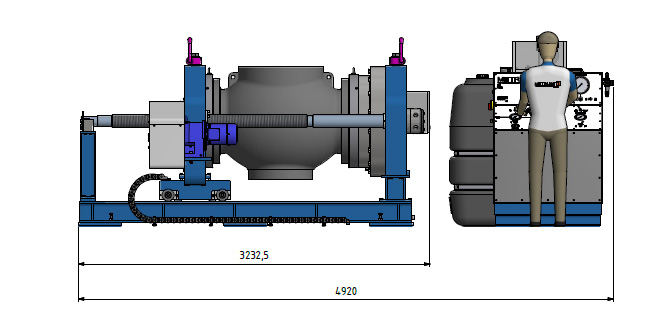

The METRUS CSV 280/600 test stand was specially developed for testing 3-way control valves (mixing valves and distributors) with nominal diameters ranging from DN 100 (4") to DN 600 (24"). Valves in straight-through form can also be tested. Seat and body tests can be carried out with various media.

The clamping unit of the CSV 280/600 has a load capacity of up to 2800 kN (≈ 280 t). The test pressure is set, among other things, via the specially developed precision needle valves on the 3-way valve head.

All functions are operated from the control panel. The required test pressure is available at the pressure inlet valves and can be read off the test pressure gauge on the control stand.

Basic features

- Clamping range: DN100-DN600 4“-24“

- Clamping force: 280 to

- Way of clamping: 3-way control valves

- Aux. pressure: air up to 6 bar

- Pressure piping: PN600 bar stainless steel

- Seat leakage test with air up to 6 bar

- Electric driven clamping spindle

- Stainless steel control panel

- Anodized, aluminium front panel

- Maintenance free vacuum system

- Gauge quick connection for tool free change of gauges (2x)

- METRUS Precision valves

Options

- External testing adapter - for testing valves larger than DN400 / 16’’ beside the calmping unit

- Gauge turret for 4+1 gauges

- Set point adjuster 0-10V and 0-20mA for controlling actuators

- Safety pressure limitation system

- CRS - Computer Registration System with panel PC

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

CSV 50/200 M – Modular Test Bench for Control and Shut-off Valves

The CSV 50/200 M is a next-generation modular test bench designed for precise and reliable testing of control and shut-off valves. Based on a proven platform, it now features an expanded modular architecture. With eleven optional modules — including CRS with laser bubble counter, bidirectional air/water testing, a motorized clamping drive, and a digital control panel — the system can be individually configured to meet the highest performance and flexibility requirements.

Figure may contain options.

Basic features

- Clamping range: DN10-DN200 ⅜"- 8"

- Clamping force: 50 tons

- Way of clamping: Automatic sealing heads

- Aux. pressure: Air up to 6 bar / 87 PSI

- Pressure piping: PN600 bar stainless steel

- Shell test with water up to 600 bar / 8700 PSI

- Seat leakage test with air up to 6 bar / 87 PSI

- Bubble counter

- Stainless steel control panel

- Anodized, chemical resistant front panel

- Stainless steel two chamber water tank

- Additional filling pump

- Maintenance free vacuum system

- Gauge quick connection for tool free change of gauges (2x)

- METRUS Precision valves

Modules

- CRS computer registration system wiht laser bubble counter

- Flow meter for leak measurement with air/digital for CRS

- Flow meter for leak measurement with air/analogue

- Laser bubble counter without CRS

- Setpoint transmitter 0-20mA and 0-24V DC

- Bidirectional testing with low-pressure air

- Bidirectional testing with higt-pressure water

- Elektric drive for the clamping spindle

- Protective enclosure

- Digital control panel

- Contact pressure gauge for test pressure limitation

Max. Test Pressure

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Valve World Expo

Valve World Expo