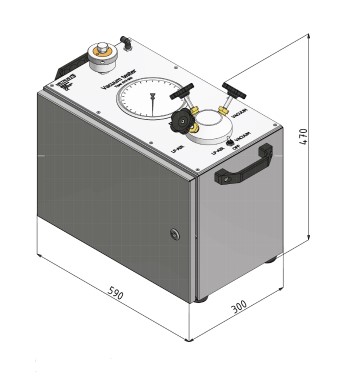

VTM - Vacuum Tester Mobile

With our VTM, you receive a mobile test stand specifically designed for vacuum, venting, and bleeding valves. The electrically driven vacuum pump enables a test pressure of up to -900 mbar, while the electrically driven compressor achieves pressures of up to 500 mbar. Vacuum sealing plates are available for nominal diameters up to DN600.

The compact lightweight design, the anodized and chemical-resistant front panel, and the stainless-steel housing ensure the easy-to-clean handling you expect from METRUS products.

Basic features

- Test pressure: electrical driven vacuum pump up to -900 mbar

- Electrical driven compressor up to 500 mbar

- Vacuum sealing plates up to DN 400 / 16’’

- Mobile unit in stainless steel housing

- Anodized, chemical resistant front panel

- Compact leight weight design

- Gauge quick connection for tool free change of gauges and sensors

- METRUS precision valves

Options

- Vacuum sealing plates up to DN 600 / 24’’

- METRUS Free CRS - free of charge computer registration system

- Pressure measuring through WIKA pressure sensor (0,2% accuracy)

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

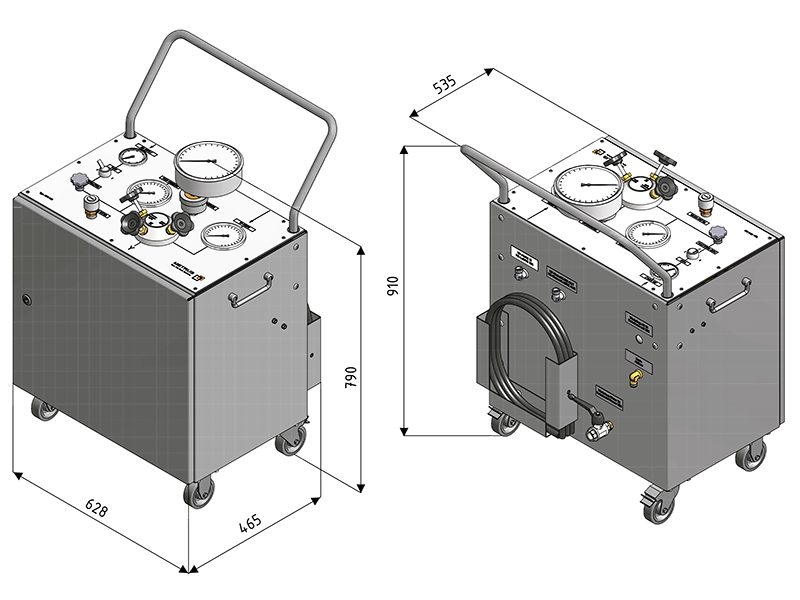

From time to time, there is a need to perform high-pressure tests on valves, fittings, pipelines, or pressure vessels of various designs that cannot be easily clamped into a test rig. This is especially relevant when the test bodies need to be examined directly on-site.

To address this need, we developed our mobile pressure generator MPU. With this easily transportable and compact device, you can perform high-pressure tests almost anywhere: using water via the integrated pump or gas via an external pressure source. The durable stainless-steel housing and proven METRUS valve technology ensure easy and safe operation at any location. Depending on the model variant, test pressures of up to 1,000 bar are possible.

Basic features

- Test fluid: Water via ext. supply up to 600 bar

- Highpressure air and gas via ext. supply up to 300 bar

- Pressure piping: PN600 bar stainless steel

- mobile unit in stainless steel housing

- 5m Highpressure hose

- Anodized, chemical resistant front panel

- Gauge quick connection for tool free change of gauges

- METRUS Precision valves

Options

- Vacuum sealing plates up to DN 600 / 24’’

- METRUS Free CRS - free of charge computer registration system

- Pressure measuring through WIKA pressure sensor (0,2% accuracy)

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

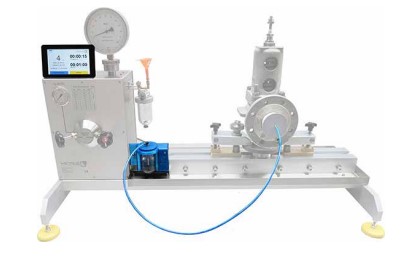

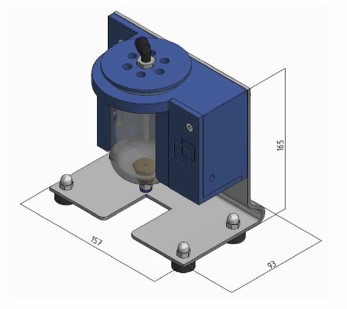

The METRUS Laser Bubble Counter is designed to make the leakage testing of valves more efficient and precise. Various standards define the requirements for tightness and allowable leaks, which are crucial for valve testing. These include API 527 for safety valves, EN 60534-4 and ANSI FCI 70/2 for control valves, and EN 12266 for shut-off valves.

The Laser Bubble Counter is supplied with a set of three different tubes, each marked to easily adjust the correct water level. The precise measurement values are displayed in bubbles per minute or per hour, allowing for accurate leak detection. Operation is intuitive, with control through a user-friendly touchscreen display. Additionally, the delay time and measurement duration can be individually adjusted, providing flexibility in its application.

The measurements comply with recognized standards such as API 527, EN 60534-4, and DIN EN 3230, ensuring reliable leak detection. The bubble counter operates with a universal power supply ranging from 100 to 240V at 50Hz/60Hz, making it adaptable for various environments.

Thanks to its easy integration, the Laser Bubble Counter is compatible with both new (integrated) and existing test bench installations. It delivers fast and precise results, ensuring a reliable valve evaluation. Developed according to the latest standards, the bubble counter offers a future-proof solution. Its versatility makes it suitable for safety, control, and shut-off valves, making it a valuable tool for a wide range of testing processes.

Choose the Laser Bubble Counter to enhance the efficiency and precision of your testing processes. Contact us for more information or a personalized offer.

Specifications

- Result displayed in bubbles per minute or bubbles per hour

- Operation via touch screen display

- Adjustable delay time

- Adjustable measuring time

- Measuring in accordance with DIN60534-4:2006, DIN3230 and API 527

- Power supply 100-240V ~ 50Hz/60Hz

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

The METRUS Laser Bubble Counter was developed to make the leakage testing of valves more efficient and precise. Various standards define the requirements for tightness and allowable leakage, which are essential for valve testing. These include, among others, API 527 for safety valves, EN 60534-4 and ANSI FCI 70/2 for control valves, as well as EN 12266 for shut-off valves.

The Laser Bubble Counter comes with a set of three different tubes, which are marked accordingly to correctly set the water level height. The precise measurements are displayed in bubbles per minute or bubbles per hour, enabling accurate leakage determination. Operation and control are carried out via a user-friendly touchscreen display, making handling very intuitive. Additionally, users can adjust the delay time and the measurement duration individually, which makes the counter highly versatile.

The measurements comply with recognized standards such as API 527, EN 60534-4, and DIN EN 3230, ensuring reliable leakage detection. It delivers fast and precise results, providing a dependable evaluation of valves. Developed according to the latest standards, the bubble counter is a future-proof solution. Its versatility allows it to be used for safety, control, and shut-off valves, making it a valuable tool for a wide range of testing processes.

Choose the Laser Bubble Counter to enhance the efficiency and precision of your testing processes. Contact us for more information or to request a customized quote.

Specifications

- Result displayed in bubbles per minute or bubbles per hour

- Operation via touch screen display

- Adjustable delay time

- Adjustable measuring time

- Measuring in accordance with

- DIN60534-4:2006, DIN3230 and API 527

- Power supply 100-240V ~ 50Hz/60Hz

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

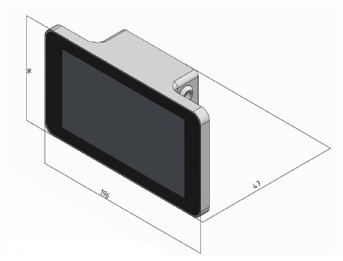

Do you need setpoints for your electric valve actuators? These can be continuously adjusted for voltage 0-24 V as well as current 4-20 mA via separate potentiometers. Our electrical setpoint adjuster is equipped for use with ATEX actuators. It is optionally integrated with a swivelling support arm on the test bench or also available as a stand-alone unit.

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

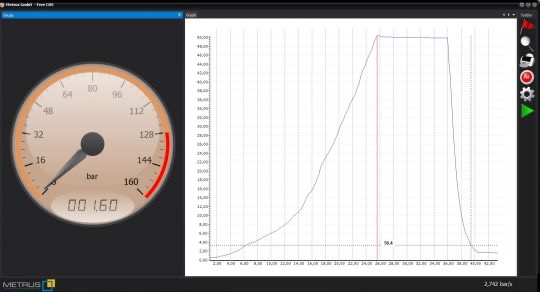

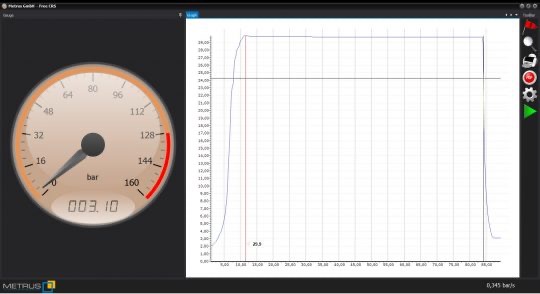

Free CRS – Free Computer Registration Software

You need a new test bench with a software or you want to extend your old METRUS test stand with one? Basically, you just want or need to print a test report with a pressure curve from time to time? Then our Free-CRS is the perfect solution for you. This software contains everything you need for digital testing. If you purchase a new METRUS test bench, we provide you this product free of charge.

Free of charge CRS software for METRUS test benches

You are looking for a test bench with a CRS – Computer Registration System or you consider upgrading your METRUS test bench with a CRS? However, at the end of the day all you actually intent to do is record a pressure graph and print a report from time to time. If that is your situation FreeCRS is the perfect solution, containing all the features you really need.

Simple installation

FreeCRS is available as a 32bit or 64 bit version for Windows operating systems. After running the installation routine the software is ready to test straight away.

Automatic configuration

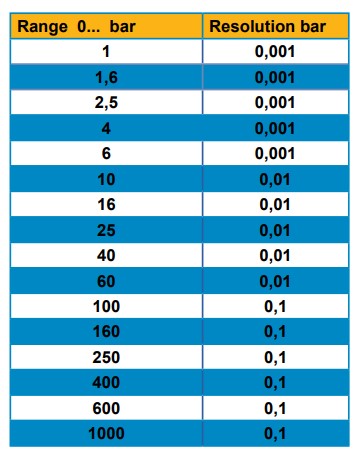

FreeCRS is designed to work with Wika USB pressure transducers. Plug-and-test. ( https://www.wika.com/en-en/cpt2500.WIKA )

The plugged in sensor is recognized and its range and unit are retrieved by the FreeCRS software, configuring itself without further user interaction. If a different measuring range is required, simply unplug the sensor in use and plug in the one you need. FreeCRS will update its configuration automatically for you to carry on testing instantly.

Testing set pressure or pressure drop

At the end of a recording FreeCRS automatically places the result cursor on the maximum value of the pressure diagram. When testing safety valves, this value is often used as the set pressure. If required the result cursor may be placed elsewhere with a simple double click, using zoom functions to analyze relevant diagram sections if necessary.

Furthermore an option is available to calculate the pressure drop between the result cursor and the end value of the recording (in bar/s, bar/min or bar/h). Using this feature makes FreeCRS the perfect solution to carry out leakage or tightness tests.

Printing or saving reports to PDF

Once recorded the test report is ready for printing on the standard printer. Alternatively (or in addition) FreeCRS generates a PDF file of the test report with a simple button click.

For those favoring the digital PDF report FreeCRS offers an additional feature to increase working efficiency. Simply enter a default report name and FreeCRS will generate a PDF file without any further user interaction. The file name of the report is generated automatically from the default name and a counter value.

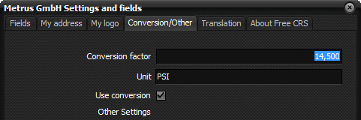

Conversion into any possible unit

Your customers require tests to be carried out in PSI or kg/cm²? No problem. The default pressure unit [bar] of FreeCRS can be converted into any possible alternative unit. All you need to do is enter a conversion factor and a unit name. The entire software including scale and result will instantly change into the conversion mode, using the unit you need.

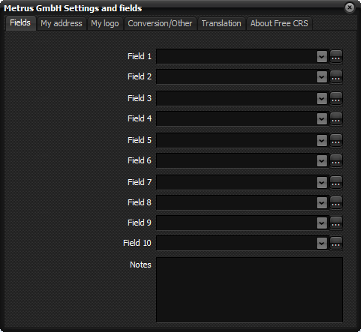

10 configurable data fields

A proper test report always requires a number of information to be presented with the result. Those could be data of the test sample as well as customer names or job numbers. To enter bring those data to the test report FreeCRS offers 10 single line data fields as one multi line field (e.g. for notes). Those can be named and used as per your specific needs.

Customizing the report

FreeCRS includes a report template ready to use. Your company address as well as your company logo is added to it without any in depth software knowledge. For those requiring more sophisticated modifications and report designs, FreeCRS offers a built in report designer.

Free CRS is automatic update

Like any other METRUS software, FeeCRS includes an automatic update function, ensuring you to always get the latest version. It is left to you to start the automatic update manually or have the software check along every software start.

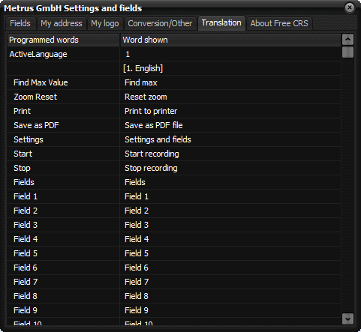

Free CRS is multi lingual

We offer FreeCRS in German and English editions. Beyond those two languages you may translate the entire software into any Windows supported language. Simply translate a list of appr. 50 words and FreeCRS will start in your required language.

Customizing the report

FreeCRS includes a report template ready to use. Your company address as well as your company logo is added to it without any in depth software knowledge. For those requiring more sophisticated modifications and report designs, FreeCRS offers a built in report designer.

Free CRS is truly free of charge

No strings attached – FreeCRS is truly free of charge. All you need in addition is a Wika CPT2500 pressure transducer of your preferred measuring range. Having an accuracy class of 0.2% (of range) a single sensor already covers a very interesting working range. You are free to order these sensors via METRUS or from Wika directly.

What if you need more?

FreeCRS is tailored to suit the demands of a simple pressure test. It benefits form simple installation, no configuration requirements, ease of use and simple customization. To fulfill those demands we decided to not build in a database system and to work with a single pressure channel. For applications that go beyond those specifications we offer a flexible, multi-channel, database integrated solution called METRUS CRS.

Funktionsumfang

- Automatic recognition of WIKA CPT2500 transducers - no setting up of sensor parameters

- Pressure recording and diagram displaying in real time

- Simple intuitive utilisation

- Automatic maximum pressure identification

- Manual correction of set pressure point

- Printed reports with logo and address

- Direct PDF export of test reports

Was Sie benötigen

- State of the art computer with Win XP, Vista or Win 7 and one free USB port

- METRUS Free CRS: Do you have a Metrus test bench? Please contact us to receive the download link

- WIKA CPT2500 Transduce

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

Full CRS - Full Computer Registration Software

The full version of our Metrus Free CRS comes with database integration and access to up to 8 sensors. It can be customized to meet your specific needs and offers a wide range of features and tools.

Leakage calculation and testing are performed according to EN60534-4 and EN12266 with high measurement accuracy using the proprietary METRUS analog-digital converter (PC box). Separate testing of the housing, seat leakage, and set pressure for safety valves is possible. During safety valve testing, individual distinctions can be made between leakage point, pop pressure, opening pressure, and closing pressure.

Measurement data recording and graphical representation are carried out on an industrial panel PC with a touchscreen. Test reports can be customized with your company logo and address and are freely configurable. Additionally, it is possible to directly export test reports as PDF files to a predefined network path. The evaluation is performed automatically and indicates whether the test has passed or failed. Optionally, integration with a higher-level ERP system is also possible.

What is METRUS CRS?

CRS stands for Computer Registration System. In the world of test benches, it refers to a system that transfers test results from measuring devices to a computer. Instead of manually recording measurements on paper, METRUS CRS tracks the measurements and displays them in graphs. Instead of using form inputs, METRUS CRS stores the results digitally, allowing users to either print them or save them in PDF format.

It is not a PLC (Programmable Logic Controller) but merely a system for recording measurement values. This means that METRUS CRS does not control the test bench actions but records and displays the results.

A CRS typically consists of the following components:

- Software running on a computer

- Sensors monitoring the test bench parameters (e.g., pressure, flow, stroke, temperature)

- Electronics to connect the sensors to the computer

METRUS uses proprietary electronics, referred to as the "PC-Box," to convert analog sensor signals into digital data that can be processed by the software. METRUS CRS is usually delivered alongside METRUS test benches, but it can also be integrated into existing METRUS test benches.

METRUS CRS is a database solution that stores all relevant data, such as test data, object data (data of the objects being tested), customer data, and sensor data. It can work with either a MySQL database or a Microsoft SQL database, depending on customer requirements. A migration from one database platform to another is possible at any time.

Flexibility of METRUS CRS Software

The METRUS CRS Software is a highly flexible platform that can be tailored to specific needs. It offers a wide range of features and tools, including measuring devices, graphs, and database management. With its scripting technology, customized applications can be developed, such as:

- Safety valve testing (METRUS CRS SV)

- Control valve testing (METRUS CRS CSV)

The core of these specific applications is the same. The system allows for the expansion and optimization of existing test benches to meet the specific requirements of a company or industry.

The specific applications for safety valve testing (SV) and control valve testing (CSV) provide everything needed for complete and standards-compliant testing. They include implementations of key testing standards such as API 527, EN 12266, or other recognized standards. If a less common standard is required, it can be integrated through custom adaptation.

METRUS CRS thus offers complete flexibility to optimize your testing processes and ensure that all requirements and standards are reliably met.

CRS-SV for safety valves

- Leak calculation and detection in accordance with API 527

- METRUS analogue / digital converter (PC-Box) with 0.05% accuracy.

- Separate tests and diagrams for set pressure and seat leakage test

- 4 result cursors:

-

- Leaking point

-

- Popping pressure

-

- Set pressure

-

- Reseating pressure

- Real-time measurement and visualisation

- Simple and intuitive operation via industrial panel PC and touch screen

- 8 sensor ports

- Individual selection of parameter dimensions

- Individually designed test reports

- PDF export with a single button click

- Optional input of additional test results

- Display of test pressure ramp rate

- Automatic passed/failed analysis

- Free support via remote desktop

CRS-SV for safety valves-options

- Connection to existing ERP-System

- Visualization of 2 parameters in combination. For example: pressure-lift diagram

- Electronic sign pad for 2 digital signatures on the test report

CRS-CSV for control und shut-off valves

- Leak calculation and detection in accordance with EN 60534-4 • FCI 70-2 • EN 12266-2

- METRUS analogue / digital converter (PC-Box) with 0.05% accuracy.

- Separate tests and diagrams for set pressure and seat leakage test

- Real-time measurement and visualisation

- Simple and intuitive operation via industrial

- panel PC and touch screen

- 8 sensor ports

- Individual selection of parameter dimensions

- Individually designed test reports

- PDF export with a single button click

- Optional input of additional test results

- Display of test pressure ramp rate

- Automatic passed/failed analysis

- Free support via remote desktop

CRS-CSV for control und shut-off valves - options

- Connection to existing ERP-System

- Visualization of 2 parameters in combination For example: pressure-lift diagram

- Electronic sign pad for 2 digital signatures on the test report

Product inquiry

Product inquiry

Visual Seat Leakage Test with Seatinspec

An essential part of valve testing is checking the tightness at the valve seat. For larger nominal diameters, it can be particularly helpful to visually identify the exact position of a leak, enabling quick and targeted corrections to the valve seat.

To meet this need, METRUS offers the visual seat leakage test option Seatinspec. A specially developed spacer can be inserted between the valve and the pressure head without the need for tools. This provides sufficient space to inspect the area using an endoscope camera on the pressure-free side.

Thanks to this additional visual assessment, the cause of the leakage can be quickly identified and resolved. Seatinspec is a valuable enhancement for the testing and maintenance of valves, particularly for large nominal diameters.

The endoscope camera ist supplied in transport bag.

Specifications

- Suitable for all CSV Test Benches

- Working range DN50 -DN200

- Easy access with special adaptor

- Visiualising through endoscope camera

- Photo and video recording of the seat area under test pressure possible

- For older METRUS test benches as retrofit available

Product inquiry

External Testing Adapter for Oversized Valves

For oversized valves that you rarely need to test, it is usually not cost-effective to purchase a large valve test bench. Such a test bench would likely exceed your budget and be unsuitable for the daily testing of smaller sizes.

When dimensioning your new test bench, focus on the 80% of valve sizes you will most frequently need to test. For oversized valves that need to be tested only occasionally, such as once a week, METRUS offers the external testing adapter. This adapter is clamped into the test bench’s clamping unit and provides two high-pressure hoses for connecting the blind-flanged valve positioned next to the test bench.

This allows you to use all the features of your test bench – such as filling, evacuation, and high-pressure testing – even for a valve that does not fit into the clamping unit.

Product inquiry

BAUER Compressors

In the field of compressor systems, the Munich-based company BAUER ranks among the leading and most reliable suppliers worldwide. A comprehensive service network ensures that you receive expert support and maintenance for a BAUER compressor, even in remote locations.

This is why METRUS has been exclusively relying on BAUER Compressors for many years. To ensure you get the best value for your investment, it is your choice whether to purchase the compressor directly from BAUER based on our recommendations, or as part of a complete package through METRUS. Should you choose to source the compressor via METRUS, we deliberately avoid adding high mark-ups, only charging for the effort required to set up the entire system and perform the final testing.

Valve World Expo

Valve World Expo