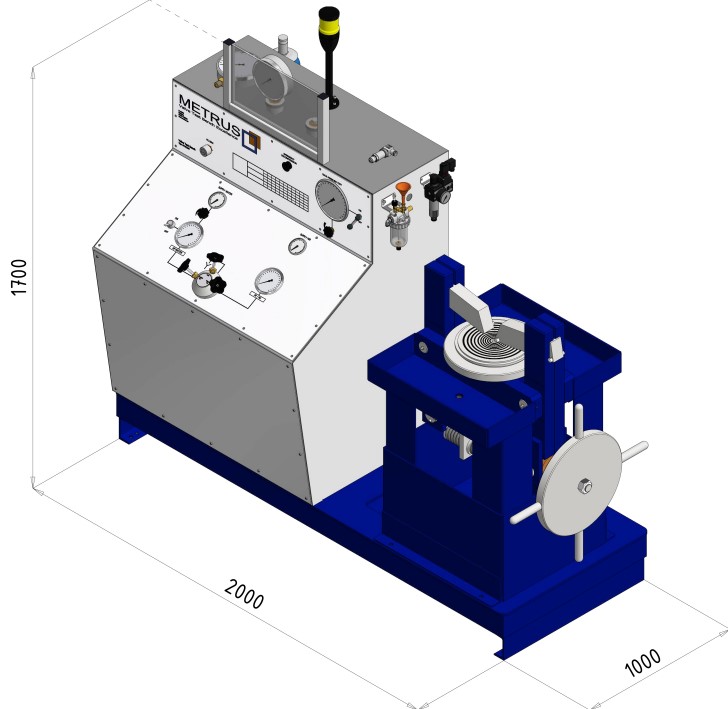

SV 20/200 PA

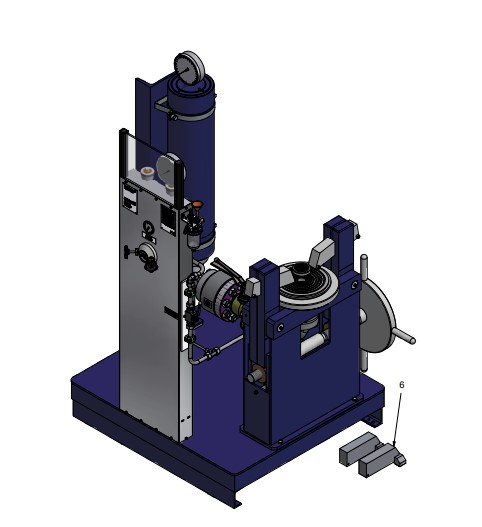

The SV 20/200 test bench is designed for testing flanged valves up to a nominal diameter of DN 200 / 8". It is particularly suitable for setting safety valves, for example, after repairs. The test valves are clamped only on one side (bottom), with the opposite side left open. The test piece is clamped by two clamping jaws at the clamping unit, which can be adjusted in height depending on the flange size.

Only air/nitrogen should be used as test media. The test pressure is regulated via precision needle valves on the valve head. The pressure at the valve head is displayed on the primary pressure gauge on the front plate.

The test pressure gauge is connected via two parallel quick coupling gauges (G½") at the top of the control panel. The parallel connectors allow the use of a pressure sensor or a comparison gauge in addition to the actual test pressure gauge.

On the right side of the control panel, a bubble tester is mounted, which is connected to the valve outlet via an air hose and a rubber plug.

Figure may contain options.

Basic features

- Clamping range: DN15-DN400 ½''- 16''

- alternatively: DN15-DN200 ½'' - 8''

- Clamping force: 20 to

- Way of clamping: manual fast clamping system with autom. load compensation, maintenance free

- Test fluid: Gas/air (external supply)

- Pressure piping: PN600 bar stainless steel

- Stainless steel control panel

- Bubble counter + rubber plugs up to DN 100

- Gauge quick connection for tool free change of gauges (2x)

- METRUS Precision valves

Options

- Water testing up to 600 bar / 8700 PSI

- Gauge turret for 4 + 1 gauges

- METRUS Free CRS - free of charge computer registration system

- Closed water circulation

- Media seperation

- Bladder accumulator

- Safety doors

- Other options on request

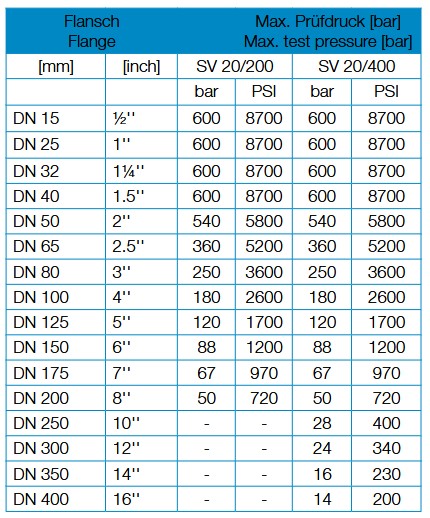

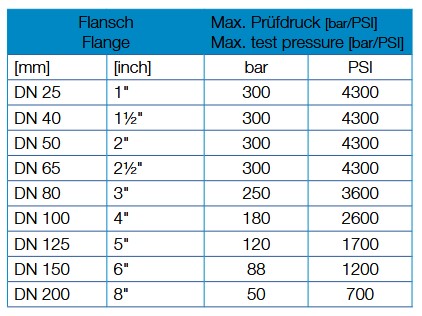

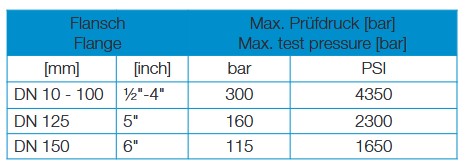

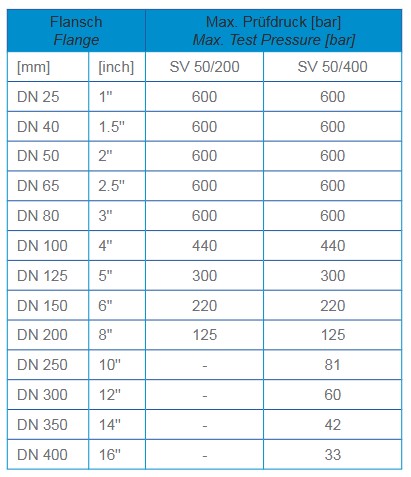

Max. Test Pressure

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

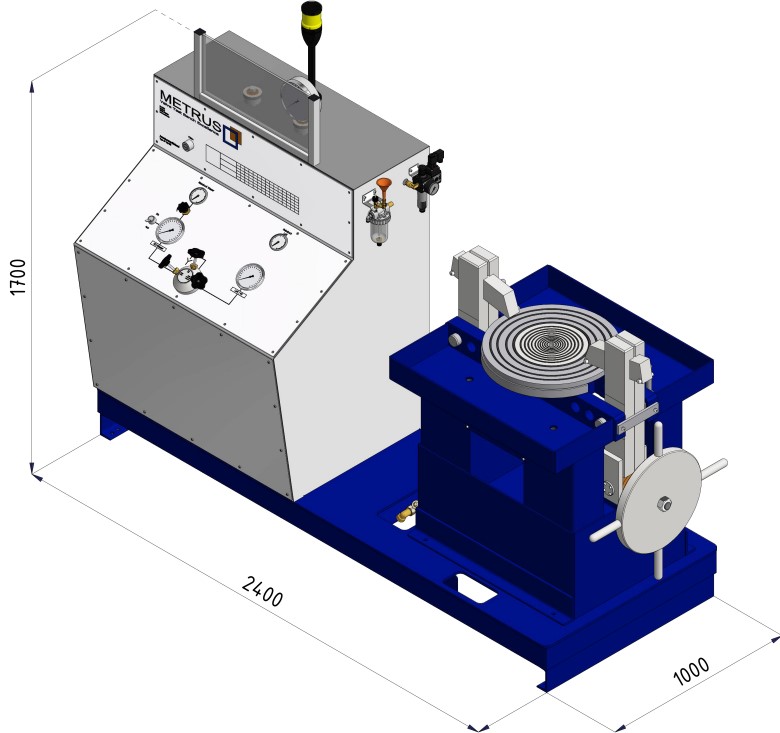

The SV 20/400 valve test bench is used for testing safety valves with flanges up to a nominal diameter of DN 400 / 16". It is particularly suitable for adjusting safety valves, as well as for leak and pressure tests on valves after repairs.

The test specimens are only closed at the clamped (lower) flange. The test item is clamped in the clamping unit with 2 clamping claws. The available test media are high-pressure air or N2 up to 300 bar from external sources, e.g. compressors (provided by the customer, not included in the scope of delivery).

The test pressure is controlled via precision needle valves on the respective valve head. The pressure at the valve head is indicated on the upstream pressure gauge on the front panel of the control stand.

The test pressure gauges are connected via two parallel pressure gauge quick connectors (G½”) on the top of the control cabinet. The parallel connections allow the use of a pressure sensor or a comparison manometer in addition to the actual test pressure manometer.

A bubble counter is mounted on the right side of the control cabinet, which can be connected to the outlet of the valve via an air hose and rubber plug.

Figure may contain options.

Basic features

- Clamping range: DN15-DN400 ½''- 16''

- alternatively: DN15-DN200 ½'' - 8''

- Clamping force: 20 to

- Way of clamping: manual fast clamping system with autom. load compensation, maintenance free

- Test fluid: Gas/air (external supply)

- Pressure piping: PN600 bar stainless steel

- Stainless steel control panel

- Bubble counter + rubber plugs up to DN 100

- Gauge quick connection for tool free change of gauges (2x)

- METRUS Precision valves

Options

- Water testing up to 600 bar / 8700 PSI

- Gauge turret for 4 + 1 gauges

- METRUS Free CRS - free of charge computer

- registration system

- Closed water circulation

- Media seperation

- Bladder accumulator

- Safety doors

- Other options on request

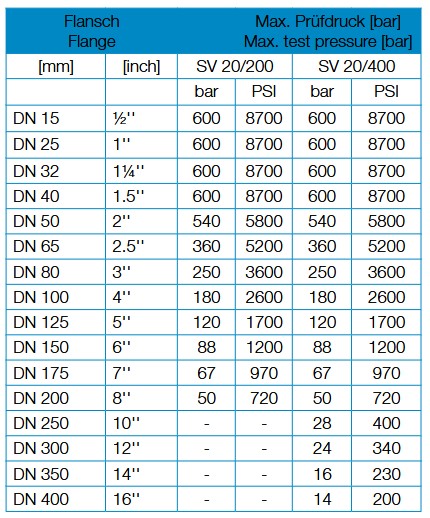

Max. Test Pressure

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

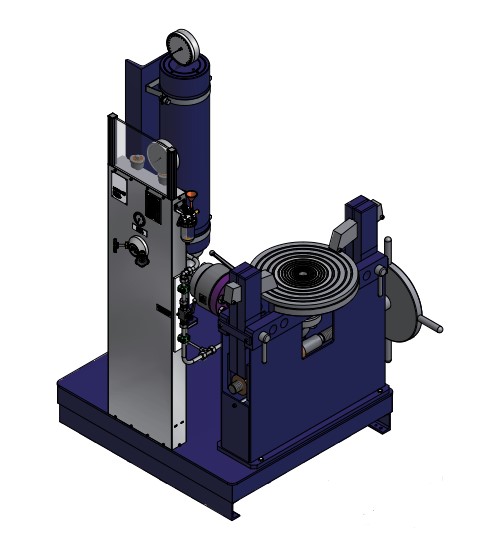

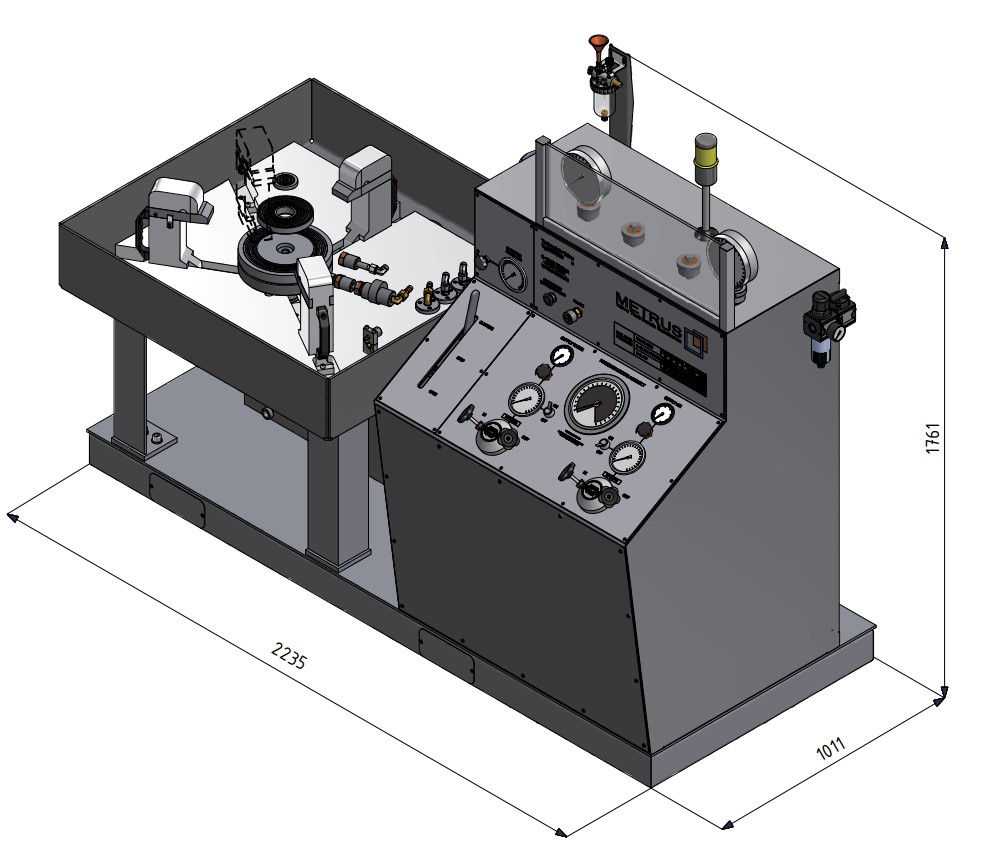

Some safety valves are designed in such a way that a high discharge capacity is achieved when the set pressure is reached. This is achieved by the space above the valve seat having a much larger volume than the inlet area. When the set pressure is reached in the valve inlet, the seat opens abruptly with maximum stroke and relieves the pressure in the valve inlet at high speed. This response is often accompanied by a strong pop noise, which is why this is also referred to as a popping test.

To simulate such a situation on a valve test bench, a corresponding gas volume and a sufficiently high flow velocity are required.

For this purpose, METRUS offers a Pop Action (PA) safety valve test stand series. A gas reservoir with a volume of 20 litres and a pipe cross-section of 2” to the test specimen provide sufficient flow energy to achieve exactly this effect during a test. For gas pressure tests up to 300 bar, the large storage volume ensures that the valve seat closes gently again on a gas cushion when the pressure drops and is not damaged by hard mechanical contact.

This test stand model is available in two versions: The SVM 20/200 PA has a working range up to DN 200 / 8”.

Figures may contain options.

Basic features

- Clamping range: DN15-DN200 ½'' - 8''

- Clamping force: 20 to

- Way of clamping: manual fast clamping system with autom. load compensation, maintenance free

- Test fluid: Gas/air (external supply)

- Pressure piping: PN600 bar stainless steel

- Stainless steel control panel

- Bubble counter + rubber plugs up to DN 100

- Gauge quick connection for tool free change of gauges (2x)

- METRUS Precision valves

- Isolatable 20 liter accumulator for soft reseating of the Valve

- 2" Piping to the clamping table

- Special needle valves to achieve “Pop-Action”

Options

- Gauge turret for 4 + 1 gauges

- METRUS Free CRS - free of charge computer registration system

Max. Test Pressure

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

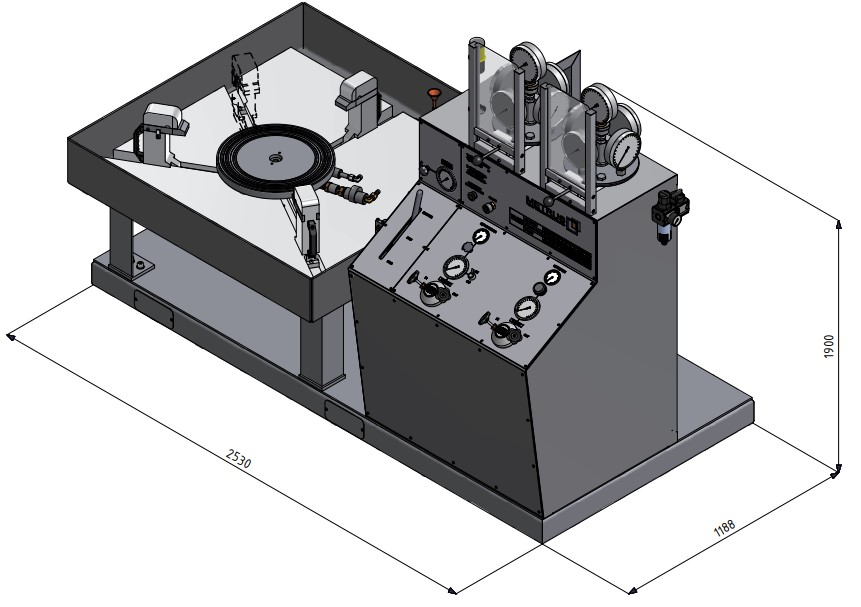

Some safety valves are designed in such a way that a high discharge capacity is achieved when the set pressure is reached. This is achieved by the space above the valve seat having a much larger volume than the inlet area. When the set pressure is reached in the valve inlet, the seat opens abruptly with maximum stroke and relieves the pressure in the valve inlet at high speed. This response is often accompanied by a strong pop noise, which is why this is also referred to as a popping test.

To simulate such a situation on a valve test bench, a corresponding gas volume and a sufficiently high flow velocity are required.

For this purpose, METRUS offers a Pop Action (PA) safety valve test stand series. A gas reservoir with a volume of 20 litres and a pipe cross-section of 2” to the test specimen provide sufficient flow energy to achieve exactly this effect during a test. For gas pressure tests up to 300 bar, the large storage volume ensures that the valve seat closes gently again on a gas cushion when the pressure drops and is not damaged by hard mechanical contact.

This test stand model is available in two versions: The SVM 20/200 PA has a working range up to DN 200 / 8”, and the SV 20/400 PA can even test valves up to DN 400 / 16”.

Figure may contain options.

Basic features

- Clamping range: DN15-DN400 ½''- 16''

- Clamping force: 20 to

- Way of clamping: manual fast clamping system with autom. load compensation, maintenance free

- Test fluid: Gas/air (external supply)

- Pressure piping: PN300 bar stainless steel

- Stainless steel control panel

- Bubble counter + rubber plugs up to DN 100

- Gauge quick connection for tool free change of gauges (2x)

- METRUS Precision valves

- Isolatable 20 liter accumulator for soft reseating of the Valve

- 2" Piping to the clamping table

- Special needle valves to achieve “Pop-Action”

Options

- Water testing up to 600 bar / 8700 PSI

- Gauge turret for 4 + 1 gauges

- METRUS Free CRS - free of charge computer registration system

- Closed water circulation

- Media seperation

- Bladder accumulator

- Safety doors

- Other options on request

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

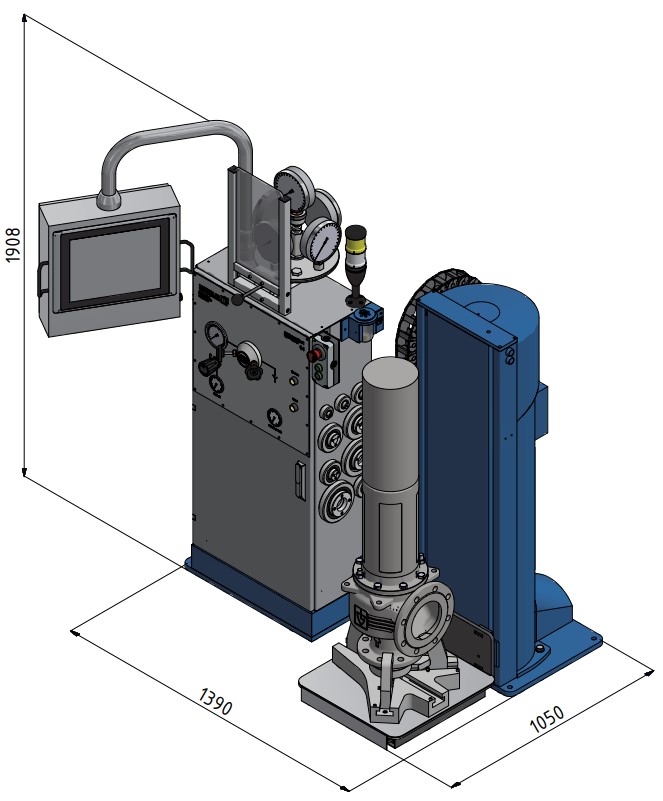

The SV 36/150 Lift valve test bench is used for testing safety valves with flanges up to nominal diameter DN 150. It is particularly suitable for adjusting safety valves, as well as for leakage and pressure tests on valves after repairs.

The test specimens are only closed at the clamped (lower) flange. The test item is clamped hydraulically in the clamping unit with 2 or 3 clamping claws. The available test media are HP air or N2 up to 300 bar from external sources, e.g. compressors (to be provided by the customer, not included in the scope of delivery). The test pressure is controlled by precision needle valves on the valve head. The pressure at the valve head is indicated on the inlet pressure gauge on the front panel of the control stand. The pressure gauge shows the gas pressure, which can be adjusted via the pressure regulator. A laser bubble counter is mounted on the right-hand side of the control cabinet, which can be connected to the outlet of the valve via an air hose and a rubber plug.

Figure may contain options.

Basic features

- Clamping range: DN15-DN150 ½'' - 6''

- Clamping force: 36 to

- Way of clamping: Manual fast clamping system with load compensation, maintenance free

- Test fluid: Gas/air (external supply)

- Pressure piping: PN 600 bar stainless steel

- Stainless steel control panel

- Bubble counter + rubber plugs up to DN100

- Gauge quick connection for tool free change of gauges (2x)

- METRUS Precision valves

Options

- Water testing up to 600 bar / 8700 PSI

- Gauge turret for 4 + 1 gauges

- METRUS Free CRS - free of charge computer registration system

- Closed water circulation

- Media seperation

- Bladder accumulator

- Safety doors

- Other options on request

Max. Test pressure

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

The SV 50/200 test bench is suitable for the testing and setting of safety valves with valve sizes ranging from DN 15 to DN 200. The test specimen is clamped with up to three adjustable clamping claws in the clamping unit. Depending on the flange size, the claws can be adjusted in height.

The available test media include ND air (up to a maximum of 10 bar) and HD water. The test pressure is controlled via precision needle valves on the valve head. The pressures at the valve heads are displayed on the pressure gauges and on the front panel. The connection of the test pressure gauges is made through two parallel pressure gauge quick couplings (G½") at the top of the control cabinet. The parallel connections allow for the use of a pressure sensor or a comparison gauge in addition to the actual test pressure gauge. A bubble counter is mounted on the left side of the control cabinet, which can be connected to the outlet of the valve via an air hose and rubber plug.

Figure may contain options.

Basic features

- Clamping range: DN15-DN200 1/2“- 8“

- Clamping force: 50 to

- Way of clamping: hydraulic clamping system with 3 and 2 claws (alternatively)

- Test fluid: Gas/air (external supply)

- Pressure piping: PN600 bar stainless steel

- Stainless steel control panel

- Anodized, chemical resistant front panel

- Bubble counter + rubber plugs up to DN 100

- Safety interlock - prevents opening of clamping unit when system is pressurized.

- Gauge quick connection for tool free change of gauges

- METRUS Precision valves

Options

- Water testing up to 600 bar / 8700 PSI

- Gauge turret for 4 + 1 gauges

- METRUS Free CRS - free of charge computer registration system

- Closed water circulation

- Media seperation

- Bladder accumulator

- Safety doors

- Other options on request

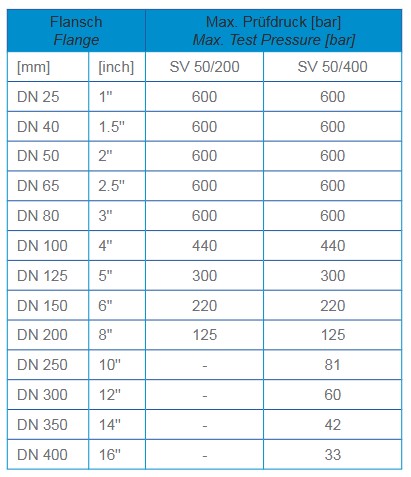

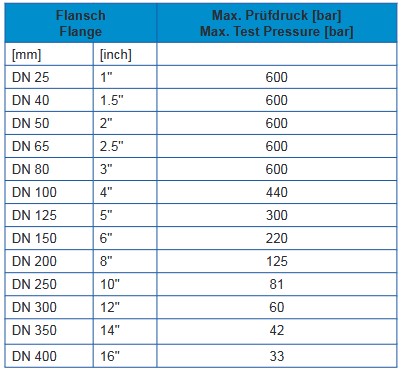

Max. Test pressure

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

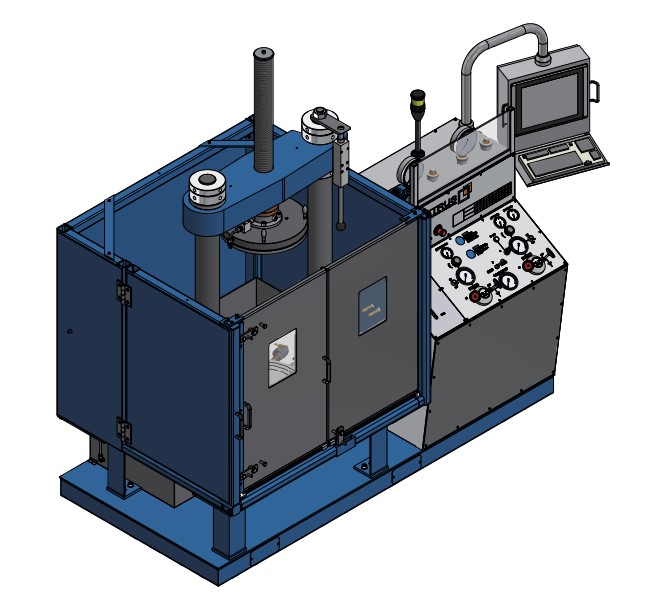

The SV 50/400 test bench is suitable for testing and setting of safety valves with valve sizes ranging from DN 10 to DN 400. The test valve is clamped with up to three adjustable clamping claws (depending on the flange size) or using the top beam in the clamping unit. The available test media are ND air (up to a maximum of 10 bar), nitrogen (up to 300 bar), and HP water (up to 600 bar).

The test pressure is controlled via precision needle valves on the valve head. The pressures at the valve heads are displayed on the pressure gauges and on the front panel. The connection of the test pressure gauges and the sensor is made via a 4-range pressure measurement unit and parallel pressure gauge quick couplings (G½") on the top of the control cabinet. The parallel connections allow the use of a pressure sensor or a comparison gauge in addition to the actual test pressure gauge.

Figure may contain options.

Basic features

- Clamping range: DN15-DN400 1/2“-16“

- Clamping force: 50 to

- Way of clamping: hydraulic clamping system with 3 and 2 claws (alternatively)

- Test fluid: Gas/air (external supply)

- Pressure piping: PN600 bar stainless steel

- Stainless steel control panel

- Anodized, chemical resistant front panel

- Bubble counter + rubber plugs up to DN 100

- Safety interlock - prevents opening of clamping unit when system is pressurized.

- Gauge quick connection for tool free change of gauges

- METRUS Precision valves

Options

- Water testing up to 600 bar / 8700 PSI

- Gauge turret for 4 + 1 gauges

- METRUS Free CRS - free of charge computer registration system

- Closed water circulation

- Media seperation

- Bladder accumulator

- Safety doors

- Other options on request

Max. Test pressure

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

The ideal partner for valve service is our SV 50/400 E universal test bench. The basis for this is our SV 50/400, supplemented by a swivelling upper beam, which enables the clamping of shut-off and control valves in straight-through form. Whether set pressure, body, or seat leakage test – this test bench offers testing possibilities for almost all types of valves. Whether high-pressure gas or water is required for the test, everything is possible with this test bench. And if the clamping table, which accommodates valves up to DN 400, is still too small, the external test adaptor for testing with blind flanges can be used. With this test bench, (almost) everything is possible!

Figure may contain options.

Basic features

- Clamping range: DN15-DN400 1/2“-16“

- Clamping force: 50 to

- Way of clamping: hydraulic clamping system with 3 and 2 claws (alternatively)

- Test fluid: Gas/air (external supply)

- Pressure piping: PN600 bar stainless steel

- Stainless steel control panel

- Anodized, chemical resistant front panel

- Bubble counter + rubber plugs up to DN 100

- Safety locking - prevents opening of clamping unit when system is pressurized.

- Gauge quick connection for tool free change of gauges

- METRUS Precision valves

Options

- Water testing up to 600 bar with test fluid separation - separate measuring system, separate needle valves, st. steel drip pan

- Closed water circuit - 2 chamber stainless steel tank, filling pump, maintenance free evacuation system

- Bladder accumulator for water testing

- Internal high pressure air generation via booster up to 400 bar.

- Safety pressure limitation system

- Gauge turret for 4+1 gauges

- Safety cabinet for clamping unit

- CRS with panel PC

- ESD Emergency Shut Off

Max. Test pressure

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Valve World Expo

Valve World Expo