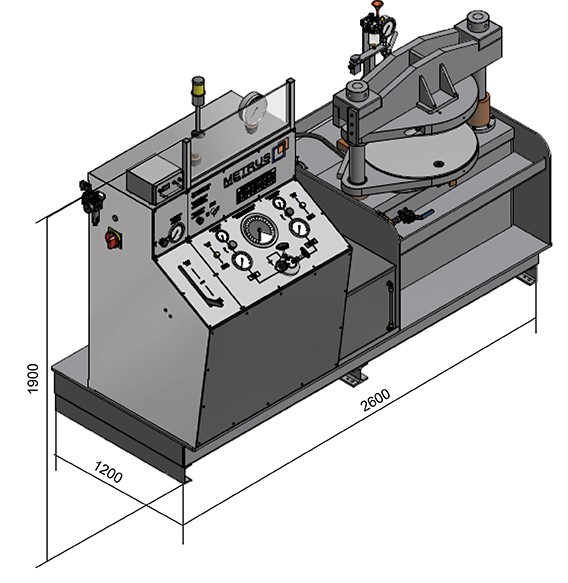

BV 36/500

In the context of maintenance and repair, butterfly valves and gate valves are mainly tested on universal or shut-off valve test rigs. However, such solutions are not efficient in the production of butterfly valves. For maximum efficiency, METRUS offers the BV series as the optimal solution for manufacturers.

Figure may contain options.

Basic features

- Clamping unit for butterfly valves up to DN 500 / 20"

- Hydraulic clamping force up to 36 tons

- Safety interlock system while valve is under pressure

- Max. test pressure at DN 500 / 20" up to 15 bar

- High pressure water test up to 60 bar from bottom side

- Low pressure air test up to 6 bar from bottom side

- METRUS Precision valves

- Anodized, chemical resistant front panels

- Stainless steel control cabinet

- Closed water cycle

- Piping and fittings in stainless steel

- Visual seat leakage control from the top

Options

- External testing adapter - for testing valves larger than DN 500 / 20" beside the calmping unit

- Gauge turret for 4 + 1 gauges

- Safety pressure limitation system

- CRS - Computer Registration System with panel PC

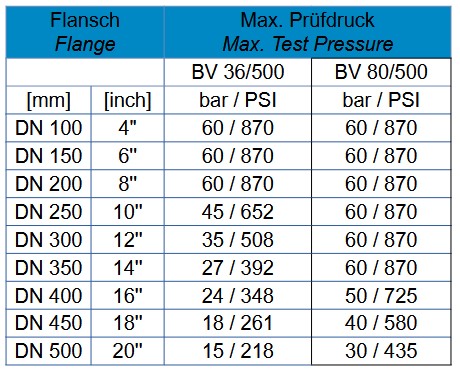

Max. Test pressure

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

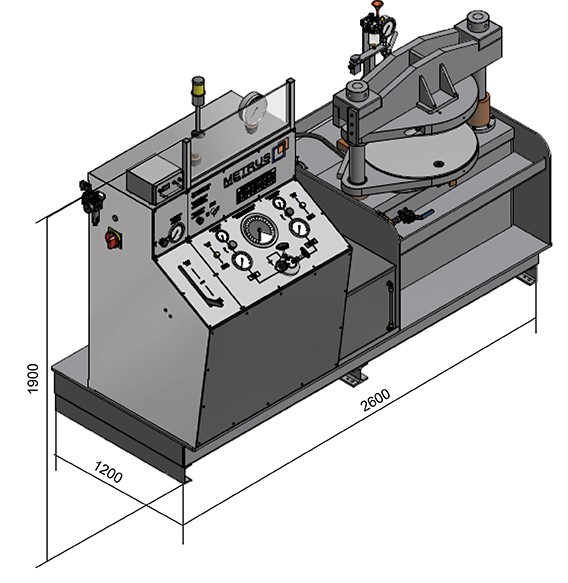

In the context of maintenance and repair, butterfly valves and gate valves are mainly tested on universal or shut-off valve test rigs. However, such solutions are not efficient in the production of butterfly valves. For maximum efficiency, METRUS offers the BV series as the optimal solution for manufacturers.

Figure may contain options.

Basic features

- Clamping unit for butterfly valves up to DN 500 / 20"

- Hydraulic clamping force up to 80 tons

- Safety interlock system while valve is under pressure

- Max. test pressure at DN 500 / 20" up to 30 bar

- High pressure water test up to 100 bar from bottom side

- Low pressure air test up to 6 bar from bottom side

- METRUS Precision valves

- Anodized, chemical resistant front panels

- Stainless steel control cabinet

- Closed water cycle

- Piping and fittings in stainless steel

- Visual seat leakage control from the top

Options

- External testing adapter - for testing valves larger than DN 500 / 20" beside the calmping unit

- Gauge turret for 4 + 1 gauges

- Safety pressure limitation system

- CRS - Computer Registration System with panel PC

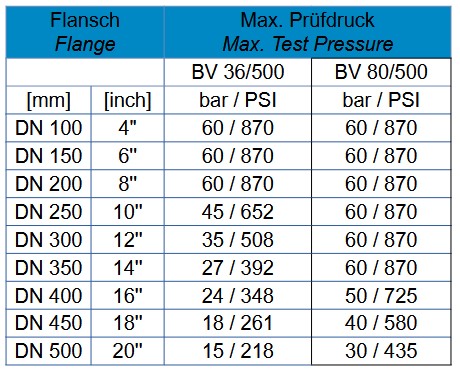

Max. Test pressure

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Product inquiry

In the context of maintenance and repair, butterfly valves and gate valves are mainly tested on universal or shut-off valve test rigs. However, such solutions are not efficient in the production of butterfly valves. For maximum efficiency, METRUS offers the BV series as the optimal solution for manufacturers.

Figure may contain options.

Basic features

- Clamping unit for butterfly valves up to DN 800 / 32"

- Hydraulic clamping force up to 150 tons

- Safety interlock system while valve is under pressure

- Max. test pressure at DN 800 / 32" up to 24 bar

- High pressure water test up to 100 bar from bottom side

- Low pressure air test up to 10 bar from bottom side

- METRUS Precision valves

- Anodized, chemical resistant front panels

- Stainless steel control cabinet

- Closed water cycle

- Piping and fittings in stainless steel

- Visual seat leakage control from the top

Options

- External testing adapter - for testing valves larger than DN 500 / 20" beside the calmping unit

- Gauge turret for 4 + 1 gauges

- Safety pressure limitation system

- CRS - Computer Registration System with panel PC

If you would like to view this content, please agree that all components required for the services mentioned above (including Google Fonts and various scripts directly from Google, Matterport and VRCloud) may be loaded and executed.

By clicking the button, you explicitly give your consent.

Valve World Expo

Valve World Expo