Online safety valve testing

Knowledge from experts for experts

Considerable cost savings with TESON

You consider offering online safety valve testing as a service to your customers; evaluate having your own online safety valve equipment for your plant or just trying to find out what online safety valve testing is all about ?

This white paper will give you an introduction into the world of online and on site safety valve testing. It explains the economical aspects of safety valve testing within maintenance and explains the physical base of online safety valve testing. It highlights important operational aspects of every day testing and what to consider as the costs of ownership.

Download

Information

1. Background

Online safety valve testing is becoming more and more prevalent in many industrial branches and countries around the world. This white paper will give you a first technical introduction into the topic, as well as the position of online testing within the maintenance strategy.

1.1. Challenge of optimal plant operation

Plant operators strictly follow one major target – earn/save money. Every plant, no matter if it is a petrochemical plant, a power station or a gas pumping station, has been financed by someone. Investors always want to achieve maximum output at minimum costs. In case of private investors the target is maximum profit. In case of public investors (e.g. public power station) the target is low costs for a municipal service.

When it comes to maintenance, a few aspects need to be considered to optimise the total profit of a plant over its lifetime:

1) Plant operation time – only when a plant is operating it does generate profit. Shut down times are very often described as „costs“ due to the lost profit of every hour the plant is not in production.

2) Plant efficiency – only a well maintained plant will achieve maximum output efficiency while it is in production. This can be described as profit/day

3) Plant safety – if a plant explodes or burns down, it will be lost or out of production for a long time. The damage caused needs to be rectified, requiring additional investment.

Being the final link in the safety chain, safety valves need frequent testing to ensure their proper operation. Being a potential reason for leakage, they need frequent service to ensure tightness. Both testing and servicing are part of the plant optimisation process. Further more safety valve testing is regulated by law and/or your insurers request a maximum of safety for the plant.

A request for maximum plant operation time on one side and maintenance and safety on the other side leads to a time conflict. The maintenance department – focused on safety and maintenance – is always asking for more shut down time than the plant operator is willing to grant them.

1.2. Online / On Site testing – key to efficient maintenance

Considering the continual conflict between maximizing plant operation and minimizing maintenance shut downs, online safety valve testing (as well as any other online service)becomes an essential part of an efficient maintenance strategy.

With many shut downs being primarily scheduled along the safety valve testing interval, testing safety valves online enables longer plant operation. Every safety valve tested online will not have to be removed from the plant to be tested on the test bench. Work load and shut down times are reduced. If a certain amount of valves can be tested online, the plant operator is often able to extend the shut down interval. In case of large safety valves and welded in safety valves even on site testing during the shut down will save you from using scaffolds, lifting gear and heavy transports, saving shut down time and money.

Online safety valve testing is less expensive than test bench testing in terms of direct testing costs. Simply because it is significantly faster to test a safety valve online / on site than testing it on the test bench in a workshop.

Online / on site safety valve testing is a win-win solution for the plant operator and the maintenance department. It sustains plant safety, reduces direct testing costs and shut down times, extending the shut down interval (plant operation) at the same time.

Technically the online safety valve test is an analysis of the set point in operational conditions. The result is therefore much more reliable than a test made in a workshop on a cold safety valve using different medium and low capacity test benches.

1.3. Derived requirements

To offer the potential described above, online safety valve testing equipment needs to meet certain requirements:

1) Accuracy – only if accurate and reliable, online safety valve testing will be considered an alternative method. As much as measurement accuracy it requires a simple and clear concept to identify the set point.

2) Mobile – with the equipment being brought to the valve it has to be light and mobile. Considering their locations of safety valves, a light test rig and light hoses are essential to comfortably test valves on high reactors and pipeline bridges.

3) Durable – being carried around every day the equipment needs to be robust and suitable for rough industrial environment. Valves are tested on hot boilers and superheaters as well as on pipelines in cold winter times. The accurate measurements must not be affected by those industrial conditions.

4) Scaleable – Meeting the variety of safety valves, the equipment should be able to test a wide range of safety valves with the same technology – from the smallest to the biggest.

5) Efficient – with labour costs as a major cost factor in the individual safety valve test, the online safety valve test must be efficient to use – to test as many valves in one shift as possible.

6) Easy to utilise – A skilled test bench technician should be able to properly operate online safety valve test equipment with short training efforts.

7) Safe in operation – testing online means working on a running plant. A maximum of working safety and fault prevention must be sustained to not accidentally disturb the plant operation or endanger the user.

2. Technical Introduction

Different online safety valve testing systems follow different technical approaches. Those might be good an efficient or complicated and clumsy, but all of them follow the same physical principle.

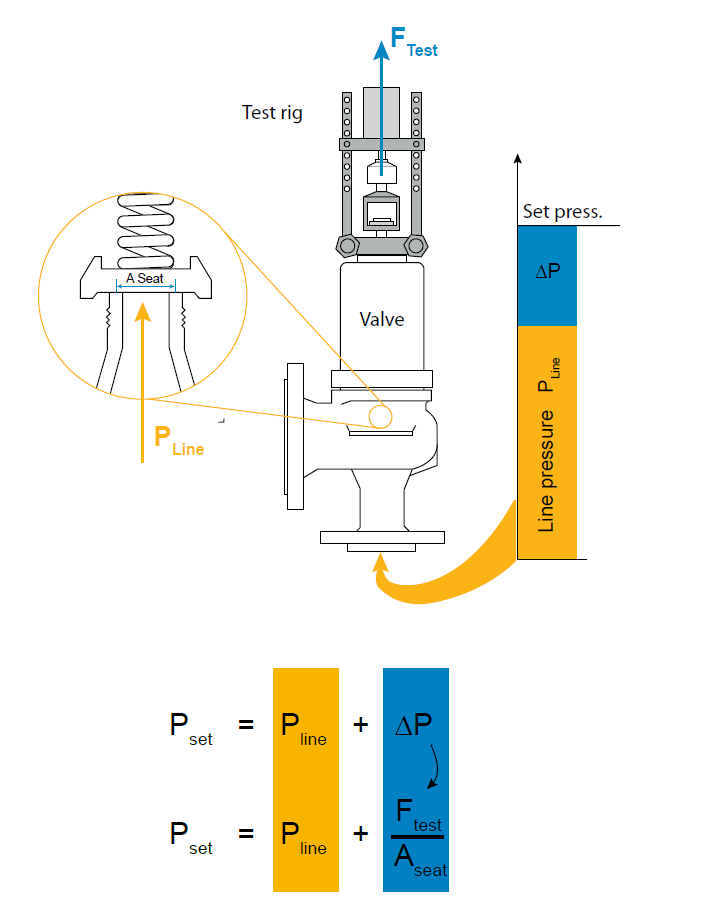

Every safety valve has a set point that is defined as the moment when it starts to lift. When online, there is a pressure – line pressure – under the safety valves disk. The line pressure is known – it is measured directly by sensors

or manometers. If the pressure difference ΔP between line pressure and set pressure can be found out, the set pressure can be calculated from:

PSet = PLine + ΔP

To find ΔP, lifting equipment – a test rig – is mounted on the safety valve. Pulling on the safety valves spindle this lifting equipment will overcome the pressure difference ΔP between line pressure and set pressure and the disk will lift. Knowing the seat area of the safety valve and the lifting force, ΔP as well as the set point is calculated according to fig. 1.

The more line pressure is to be found under a safety valve, the less force will be required to overcome ΔP. But it is not required to have line pressure. If there is no pressure, online safety valve technicians talk of a „cold“ test. Tests carried out with line pressure are called „hot“ test. Even though testing a safety valve online during plant operation (hot testing) offers the biggest benefits, cold testing during shut downs offers a significant cost saving potential as well. Especially in the case of large safety valves that would require a lot of manpower and lifting gear to be moved, the on site test (cold test) is a much better choice.

2.1. Data acquisition

To be able to test a safety valve, it is necessary to know its seat area. This data is to be found in the safety valves documentation. If not, they can be provided by the safety valve manufacturer of even be measured when dismantling the valve next time.

Pulling force, disk lift and line pressure are recorded during the lifting process and either stored digitally and displayed on a screen or printed for further analysis. Digital systems are most convenient as stored data can easy be processed in various ways and stored in databases or files.

2.2. Data presentation and analysis

The initial result of an online safety valve test is a diagram of the recorded parameters force, line pressure and spindle lift (it depends on the specific equipment if all of those parameters are available). It is the technician‘s task to find the set point within the diagram. The final result – set pressure – will be calculated as per formula in fig. 2, using the diagrams set point values.

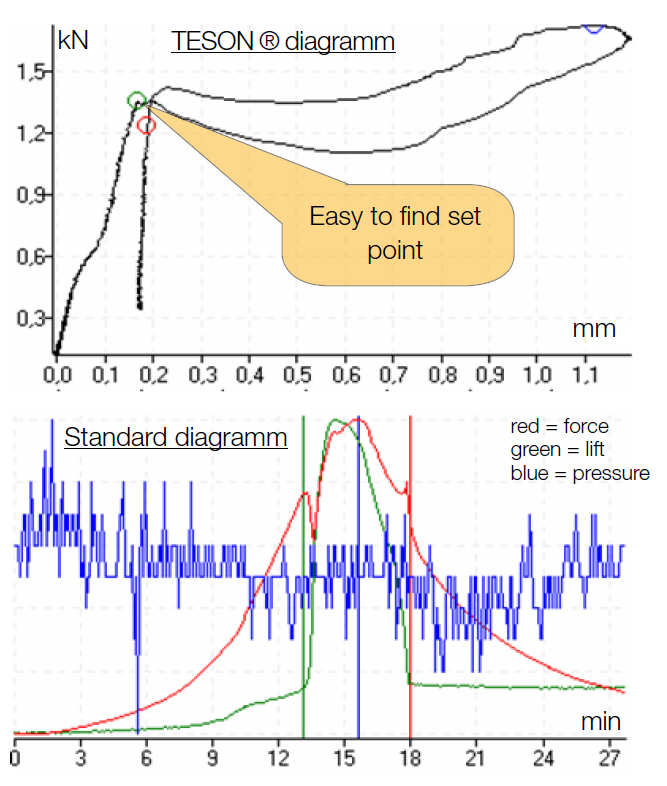

An essential measure of the over all performance and accuracy of an online safety valve testing system is how the result diagram is presented to the technician. If the information is shown in an unclear way, the technician will not be able to properly select the right set point. Missing the set point leads to wrong test results.

The TESON® diagram introduced by METRUS is a unique and revolutionary concept in finding the set point. A clear and strict set point definition and the TESON® diagram – a force – lift diagram – make set point analysis easy. Based on an easy and straight forward diagram analysis, online safety valve testing is no longer a question of long experience.

2.3. Famous errors

The result diagram will show a point where the disk starts to lift. And if the recording of data runs to the end of the lifting procedure, the diagram will show the moment when the disk reseats. From the diagram point where the disk starts to lift, the set pressure is calculated. Looking at the set pressure calculation, many technicians concluded to calculate the reseating pressure from the reseating point (incl. blow down etc.). This is absolutely wrong. It is not possible to calculate the reseating pressure form the reseating point and is different to what some vendors claim, it is not even an indication.

The formula used to calculate the set pressure describes a static scenario to be found only when the disk is seated. Once the disk lifts, the fluid discharges. The discharge will cause a significant additional dynamic force onto the valves disk, forcing it open. This force depends on the shape of the disk, position of blow down ring as well as on fluid parameters like density, fluid pressure, etc. Those dynamic forces and geometrical influences could only be measured and analysed in a laboratory analysis, but it is not at all feasible to do it in a maintenance field analysis. Only because of those dynamic forces, safety valves have what is called a „blow down“ – the valve will close only after the pressure has decreased significantly below set pressure level. The only way to seriously test blow down and reseating pressure point it is a full flow test. Online testing will not deliver correct results.

2.4. The potential use of ultrasound

For many years, ultrasound has been utilised by various vendors as an additional method to find the set point in cases the standard diagrams are hard to analyse. This can be the case when testing safety valves on liquid services.

Many system vendors today claim ultrasound to be the perfect solution to work around unclear standard diagram problems as the ultrasound diagrams show a significant diagram reaction where lift and force do not. Ultrasound „appears“ to solve those cases.

Within an extensive benchmark test, METRUS in co operation with Sweden‘s biggest nuclear power station Ringhals AB investigated the approach to use ultrasound as an additional indication for the set point on liquid service safety valves. The result of 55 tests on different valves is that the „Ultrasound point“ is completely depending on the seat condition. This result perfectly first the fact that ultrasound will detect the start to leak point and not the set point (start to lift point).

Only on a new or freshly serviced valve, the set point will be close to the ultrasound point. Even tiniest soiling or improper maintenance will cause the ultrasound to severely „drift away“ from the true set point. Within a typical online safety valve testing scenario where a valve has not bee serviced for a year or more, it is not at all recommended to use ultrasound to identify the set point.

There are still two useful applications for ultrasound within online safety valve testing. A very simple but effective use is to compare the sound level of the valve before and after the test. Comparing those sound levels will indicate if after the test (disk lift) the valve is left in a similar condition to its previous untested state. This could be first information if the valve did properly reseat and seal after it has been lifted. White Paper – Online safety valve testing METRUS Valve Test Bench Exellence

3. Operational aspects

Knowing why safety valves should be tested online and how this is done in theory, it is most helpful to get an idea of the every day questions you will have to deal with. It will enable you to imagine how online safety valve testing appears in real life.

3.1. The valve disk must lift

Plant operators are often surprised when being asked by online testing engineers whether it is a problem to open a valve. Considering the definition of the set point to be the initial moment when the disk starts to lift the safety valve disk must lift to find that point in a test diagram. It very much depends on the test equipment how long and high the valve will open, but it definitely has to open. geöffnet wird.

3.2. Valve types that can be tested

To test a safety valve, it must be possible to lift the disk and measure the force when doing so. If a safety valve has a spindle, it is possible in 95% of all cases to test it online. Some valves might require a simple spindle modification. This depends on the valve and the adapter solution how to „connect“ the test rig. Valves that do not have a spindle at all can not be tested.

Valves installed on extremely dirty fluids like bituminous crude oil should not be tested unless they are equipped with a rupture disk to keep the seat clean. Dirt could prevent the disk from sealing properly and the valve will remain leaking after the test. It the maintenance departments decision whether to agree with slightly lifting a valve or not.

Safety valves installed in EEx areas require special equipment to operate the test rig. If such equipment is available, it is important to check the specific EEx certificate for the approved EEx class and EEx area. As of now and to our best knowledge, there is no online safety valve testing system available that has an EEx approval for the whole machine. The test rigs are approved but the power unit usually has to stay outside the EEx area or have to be protected with special temporary solutions.

3.3. Operational range

A frequent question to be found in industry is „what is the highest set point and the largest nominal diameter you can test?“. According to the online testing formula of fig. 1 the set pressure is calculated from line pressure, seat area and test force. Those parameters interact. The more line pressure is to be found under the safety vales disk the less force is required to lift (test) it. A final statement can never be made as it depends on seat area, set point and line pressure, whether or not the force capacity of specific equipment will be strong enough to test a valve.

Some suppliers claim that their equipment can test „any“ safety valve. Technically speaking it means raising the line pressure will lead to a remaining test force small enough to be covered by the test equipments force capacity. As online safety valve testing should not affect the plant operation this statement is not very respectable. Usually the line pressure can not be changed significantly just to test a valve.

Thinking about the largest valves, small and medium valves are often forgotten. But those ½“ and 1“ valves built the majority of valves to be found in industry. It is a technical fact, that each measurement task requires suitable sensor ranges. Large valves require large forces and small valves usually small forces. The operational range of online safety valve test equipment is therefore not only defined by its strongest force capacity. It is a question how accurate it can deal with a variety of forces and pressures – small and large.

3.4. Working efficiency

Online safety valve testing offers major cost saving potential. In most cases it is cheaper than workshop testing after comparing direct testing costs. This of course requires the test equipment to be efficient in handling and operation.

Safety valves need to be tested at various locations within a plant. It is common to move the test equipment a few times during a test day. Different valve types to be tested require retooling of the test rig. In every day life the equipment will be packed and unpacked several times and it will require adaptation to fit the test rig on the safety valve. Valves will be located on top of tall reactors and on difficult to reach places under or behind pipelines.

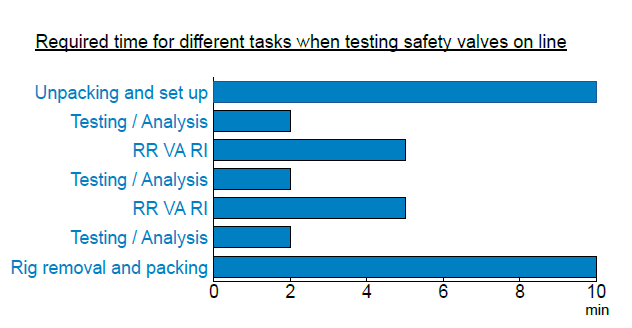

The test equipments performance is significantly defined by its mechanical performance – weight and flexibility. The time for unpacking and rigging up as well as for wiring all sensors etc. determines, how fast the individual valve test will be. And in many cases the safety valve requires adjustment. Depending on how long it takes to take the rig off the safety valve, testing and re-testing will be fast and efficient or time consuming.

Within a typical online safety valve test scenario, a valve might need to be adjusted. To adjust a valve, it requires to remove the rig (RR) adjust the valve (VA) and reinstall (RI) the rig before you can carry out the next test to see, if the adjustment was successful. This is done usually two times until a satisfying set pressure is adjusted.

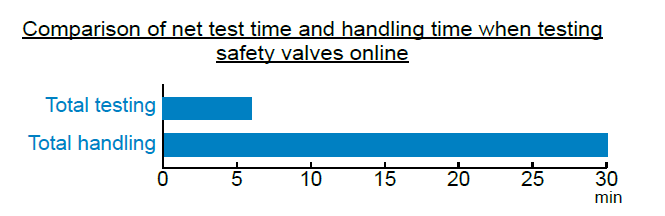

The relation between handling and testing time in average test equipment is about 1/5. It becomes obvious that total test time and efficiency are significantly depending on the test rig performance – weight, portability and speed of set up / dismantling.

As important as an efficient test rig handling is a clearly structured software or control system. The technician will have to deal with a lot of test data and to generate reports. With the TESON® system the technician controls the test completely from the software. The software should support the working process and enable the user to keep an eye on all relevant data without clicking through several hidden menu hierarchies. Data should be stored in databases and generating reports has to be flexible and easy. As most companies use individual test reports as well as overview lists, it is a must to have the software generating all those reports without additional work.

3.5. Working safety

It may happen that safety valves stay open after the test. To make sure that such event does not affect the plant operation, a concept to remotely close the safety valve, using the test rig is absolutely necessary for safe online safety valve testing.

Testing safety valves online is not at all dangerous as long as the procedure is done properly and the system performs as it should. But there are rare scenarios in which a plant disturbance could appear, especially if a safety valve stays open or gets damaged.

Online safety valve test equipment today is either manually or electronically controlled. Electronic systems support the test process and monitor test limits, taking a lot of responsibility from the technician. TESON® e.g. automatically drives the complete lifting process, monitoring all sensor signals for pre calculated test limits. But electronic systems are sensitive to power black outs as well as to software malfunctions. To deal professionally with those, the online safety valve testing system must have an extensive safety system to guarantee the safety valve will never be blocked open or damaged – whatever might happen.

Manually controlled system are not sensitive to power black outs or system failures. They leave the full control over the test process to the technician. It is up to the technician to control the lifting force and whether or not to overload a valve. Especially with manually controlled system experience plays an important role as the safety issue is basically the human factor. Despite that even manually driven system must have some safety features to respond to hardware or hydraulic malfunction.

Considering the number of parameters to be considered and monitored during an online safety valve test, digital systems are definitely superior as the chance of malfunction and power black outs is considerably small if the systems are well designed and extensively tested. Even after intensive training and years experience it is barely possible for a technician to compete with the reliability and response time of a digital system. Considering the background of online safety valve testing it is a derived requirement of the system to be safely and correctly operated with minimum skill and experience.

4. Costs of ownership

When thinking of a first time investment, it is very often the purchase price that plays an important role. But if you consider the cost saving potential of online safety valve testing or the profit you could make with a service, it becomes obvious that there is more to be considered to get a real view on the cost of ownership.

From the very fist moment employees need to be trained on how to use the equipment. And in case a trained expert leaves the company others will have to substitute him. Besides purchasing good equipment it is valuable to have a comprehensive documentation and training material, making you independent from external trainers, enabling self training. Further more suppliers should be able to offer professional training courses.

Support from your supplier will be crucial for your business. If you are facing time sensitive testing sessions and your equipment gets damaged or you come across complex questions, delays of operations or loosing your customer to the competition can cause severe loss of profit. The system vendor should be able to minimize downtimes with an intelligent support strategy. This includes 24 h availability of technical support, access to most spare parts in local markets and availability of rental equipment to substitute yours during service and repair. The more a supplier is focused on the online safety valve testing business, the better resources he will offer to support your every day work.

Like all measuring equipment, online safety valve testing systems require calibration. Sensors and measuring electronic need calibration (typically every 2-3 years) to harmonize with ISO quality standards. Suppliers must be able to either offer you a calibration service or advice you where to get such service. To minimize transportation costs, the parts and modules that need calibration should be easy to isolate for shipping.

The variety of valves to be found in industry is huge. It is not at all practical to own every type of special equipment that might be required one day to test special applications. Your investment will be significantly lower if you can own core components that cover the majority of your every day online testing needs. Your supplier should offer you special extension for rent to cover the remaining applications once they are required.

We hope this white paper could draw a picture what online safety valve testing is about. If you have any further related question, please feel free to contact METRUS at any time. It will be our pleasure to support and consult you..

Writer:

Johannes Junior

Managing Director

Curious?

Contact us through our contact form.